Features and benefits universal design serves the widest variety of applications for starting or stopping electrically operated equipment such as signal lights alarms motors automatic burners metering devices and others replacement for common flow switches from johnson penn potter taco watts hydrolevel and other manufacturers 1 npt two electrical knock outs allows connection from.

Fs251 flow switch manual.

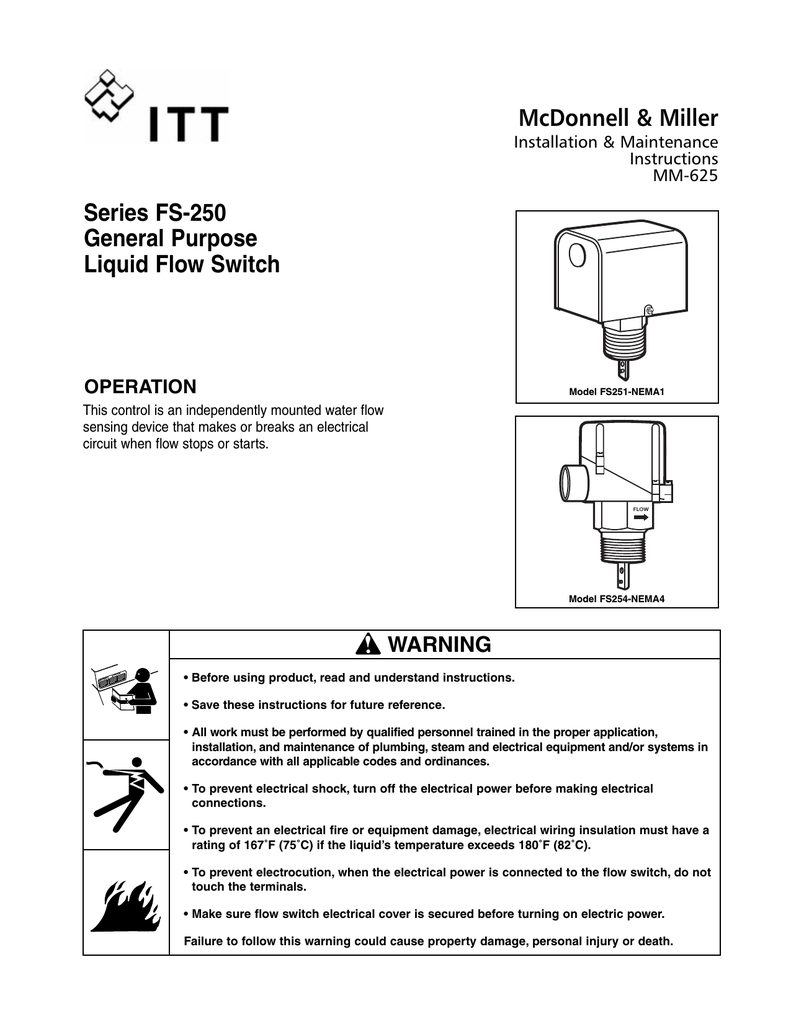

General purpose liquid flow switches the series fs250 fs251 nema1 version and fs254 nema4 version.

Do not use liquid flow switches on systems with flow velocity greater than 10 feet 3m per second.

Fs251 model part weight number description lbs.

Nema 1 ip 21 fs254.

32 120 f 0 49 c electrical enclosure rating fs251.

Do not put excessive force on cover when turning.

518 95 120100 mcdonnell.

120100 mcdonnell miller fs7 4e 1 1 4 flow switch.

Final position is with arrow on body aligned in the liquid flow direction.

Replacement for common flow switches from johnson penn potter taco watts hydrolevel and other.

Instruction manual mm 601k series fs4 3 general purpose liquid flow switch 246796 pipe flow no flow size npt maximum maximum in.

Insert the flow switch into the pipe tee.

32 250 f 0 121 c ambient temperature range t s.

Kg fs251 120611 fs251 general purpose 1 9 flow switch nema 1 0 9 fs254 120610 fs254 general purpose 1 9 flow switch nema 4 0 9 ordering information mcdonnell miller bulletin mm 626.

Features and benefits universal design serves the widest variety of applications for starting or stoppingread more.

Nema 4 ip 56.

These flow switches incorporate key changes to address customer expressed needs of greater reliability and lower flow sensing capabilities in a general purpose flow switch.

Fs251 aluminized steel fs254 aluminum housing cover fs251 polycarbonate fs254 aluminum ratings fs251 nema 1 fs254 nema 4 maximum operating pressure 160 psig 11 0 bar maximum temperature 250 f 121 c motor switch rating amperes voltage full load locked rotor pilot duty 120vac 7 4 44 4 125 va at 120 or 240 vac 240 vac 3 7 22 2 50 or 60 cycles.

Place a 1 3 8 open end wrench on the hex floats of the flow switch body to tighten to final position.

The series fs4 3 fs8 w and fs5 may be used in this situation as they will generally operate satisfactorily when installed in a vertical pipe.

Mcdonnell miller fs6 instruction manual this mcdonnell miller flow swicth is for heavy duty applications.

Mcdonnell miller fs251 general purpose flow switch with nema 1 enclosure 120611 replaces fs4 3.

Mm adjustment adjustment 2 50 69 2 50 3.

Mcdonnell miller 120611 fs251 general purpose flow switch w nema 1 enclosure universal design serves the widest variety of applications for starting or stopping electrically operated equipment such as signal lights alarms motors automatic burners metering devices and others.

However because of space limitations the only available installation may be in a vertical section of pipe.

Turn the flow switch two 2 or three 3 revolutions clockwise until tight.